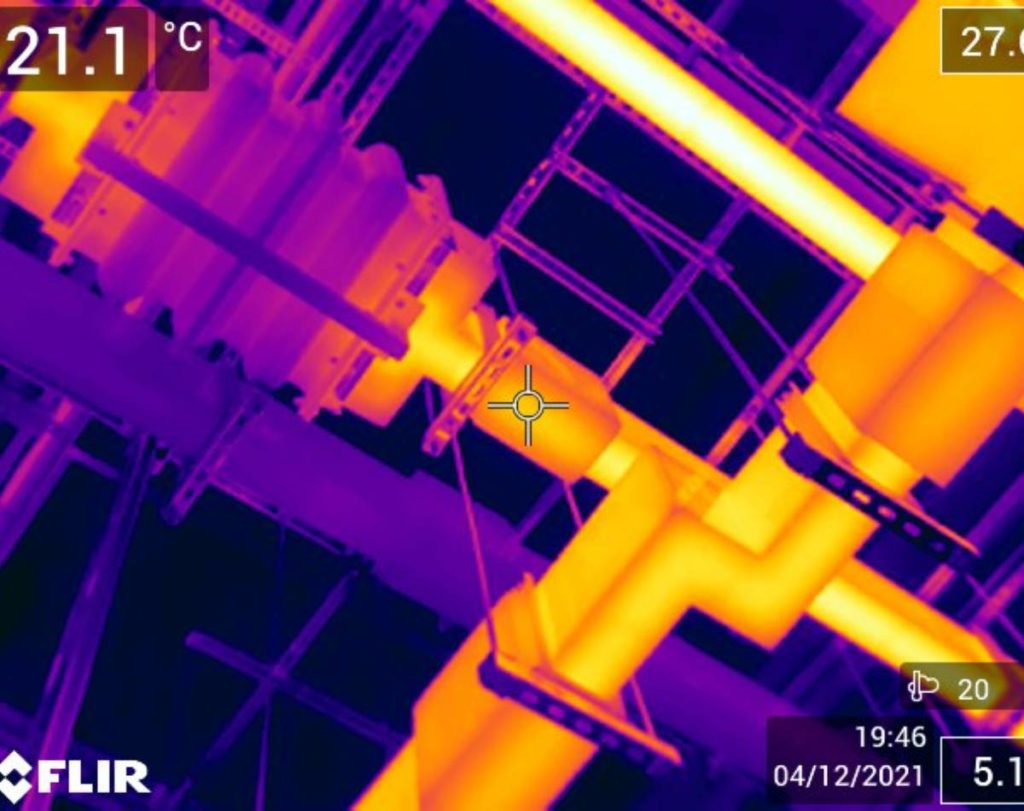

Thermal Imaging in Data Centres – How Crucial is This Service?

Data Centres are an integral part of today’s society, with all types of data and information being used day to day in our lives. With this being the case, it is essential that the equipment within data centres are looked after and regularly monitored to prevent any sort of downtime and disruption.